How Lightweight Car Batteries Are Shaping Progress

Contents

- 1 How Lightweight Car Batteries Are Shaping Progress

- 1.1 Traditional Vs. Lightweight Batteries

- 1.2 Open-Up The Technology Lightweight Car Batteries

- 1.3 How Lightweight Car Batteries Are Shaping Progress Materials

- 1.4 Performance

- 1.5 Emissions Reduction And Sustainability

- 1.6 Lightweight Car Booster Seat

- 1.7 Overcoming Challenges

- 1.8 Conclusion

- 1.9 FAQ

Lightweight car batteries lie at the heart of a transformative shift in the automotive industry. These batteries are revolutionizing how vehicles are designed, built, and operated. With traditional internal combustion engines being gradually replaced by electric and hybrid power trains, the demand for energy-efficient solutions has intensified. Lightweight car batteries address a critical challenge.

How Lightweight Car Batteries Are Shaping Progress? Manufacturers can unlock a host of benefits by significantly reducing the weight of batteries while maintaining or even enhancing their energy storage capacity.

As vehicles become more electrified and consumers seek longer driving ranges without compromising performance, lightweight car batteries emerge as a pivotal enabler of this transition, propelling the automotive sector into a new era of innovation, efficiency, and environmental consciousness.

Traditional Vs. Lightweight Batteries

Several key distinctions come to light when comparing traditional car batteries with emerging lightweight alternatives. Conventional car battery power, often lead-acid based, has long been the staple power source for internal combustion engine vehicles.

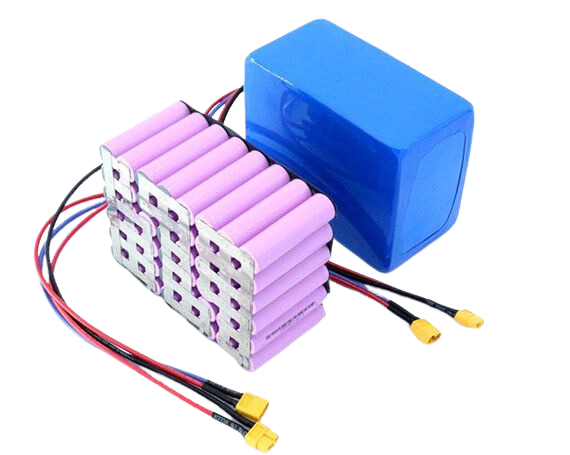

These batteries are relatively heavy and can add substantial weight to the car, impacting overall efficiency, handling, and fuel economy. In contrast, emerging lightweight car batteries leverage advanced technologies such as lithium-ion and solid-state batteries. These newer alternatives prioritize weight reduction without compromising energy storage capabilities.

Furthermore, traditional car battery power requires more frequent maintenance and has limited charge-discharge cycles, which can impact their overall lifespan. On the other hand, lightweight alternatives often exhibit better durability, longer lifespans, and the potential for faster charging, making them more convenient for consumers.

Open-Up The Technology Lightweight Car Batteries

How Lightweight Car Batteries Are Shaping Progress Materials

Lithium-ion Chemistry

-

- The use of advanced lithium-ion chemistry allows for higher energy density, enabling more energy storage in a smaller and lighter package.

Nanostructured Materials

- Nanoengineering materials like nanowires and nanotubes enhance electrode surface area, improving energy storage capacity and efficiency.

Solid-state electrolytes

- Solid-state electrolytes replace traditional liquid electrolytes, reducing the need for heavy casings and improving safety while maintaining energy efficiency.

Lightweight Composites

- Incorporating lightweight materials like carbon fibre or polymers for casings reduces overall battery weight without compromising structural integrity.

Design

Compact Form Factor

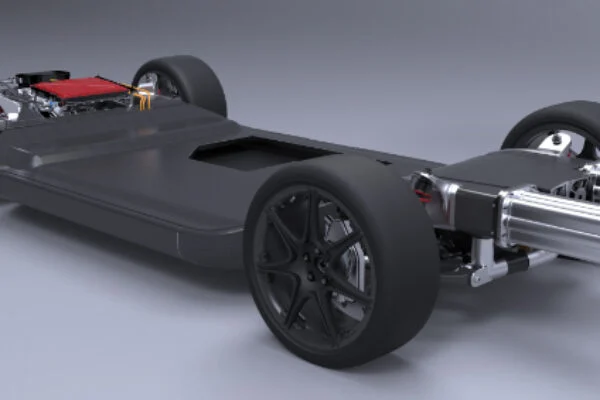

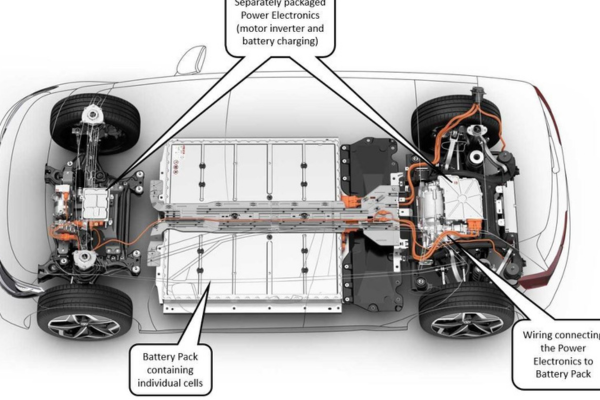

- Optimized designs arrange battery cells efficiently, reducing wasted space and allowing for better integration into the vehicle’s architecture.

Integration with Vehicle Design

- Batteries are designed to be an integral part of the vehicle’s structure, distributing weight evenly and enhancing overall balance

Thermal Management Systems:

- Advanced cooling and heating systems prevent overheating and ensure optimal operating conditions, improving battery efficiency and lifespan.

Modular Designs

- Modular battery designs allow for easy scalability, making it possible to adjust battery capacity for different vehicle models and applications.

Manufacturing Processes

Precision Manufacturing

- Improved manufacturing techniques ensure consistent cell production, enhancing performance and reliability.

Automated Assembly

- Automated assembly lines streamline production, reducing human error and optimizing battery construction for efficiency.

.Advanced Coating Methods

- Innovative coating processes for electrodes enhance energy storage capabilities while maintaining structural integrity.

Customized Manufacturing

- Tailoring manufacturing processes to specific vehicle requirements enables optimized battery performance and integration.

Fuel Economy And Lightweight Car Batteries

The relationship between lightweight car batteries and improved fuel efficiency is grounded in the fundamental principle of reducing vehicle weight to enhance energy efficiency.

In traditional internal combustion engine vehicles, every additional pound of weight requires more energy to propel the car, resulting in increased fuel consumption.

Lightweight car batteries directly address this issue by significantly reducing the weight attributed to the power storage system.

As vehicles transition towards electrification, these lighter batteries minimize the energy required to move the car, extending its driving range on a single charge. This reduction in weight translates into decreased energy demand and, consequently, reduced reliance on fossil fuels.

Performance

The reduced weight of lightweight car batteries has a pronounced positive impact on both vehicle acceleration and handling. Acceleration benefits from the principle of power-to-weight ratio, which means that a lighter vehicle requires less energy to accelerate, resulting in quicker and more responsive acceleration.

Moreover, the impact on handling is equally significant. This allows the vehicle to respond more swiftly to steering inputs and changes in direction.

With less weight to shift during cornering and braking, the vehicle maintains better stability and traction, enhancing the overall driving experience and safety. The reduced weight of lightweight car batteries not only contributes to quicker acceleration but also enhances the vehicle’s general handling characteristics, making driving more dynamic, responsive and enjoyable.

Emissions Reduction And Sustainability

- Reduced Energy Consumption: The lighter weight of these batteries leads to reduced energy consumption, resulting in lower demand for electricity and decreased reliance on fossil fuels for charging, thereby cutting down overall greenhouse gas emissions.

- Extended Electric Driving Range: Lightweight batteries enable electric vehicles to travel longer distances on a single charge, encouraging more electric-only driving and reducing the need for internal combustion engines, which emit pollutants.

- Energy Efficiency: Lighter batteries contribute to increased energy efficiency, allowing vehicles to convert a higher percentage of stored energy into actual movement, ultimately minimizing energy waste and emissions.

- Life cycle Emissions: The manufacturing of lightweight batteries may involve fewer raw materials and resources, leading to lower emissions associated with the production process itself.

- Lower Vehicle Weight: The reduced battery weight enables automakers to use smaller, more efficient power trains, which can result in further emissions reduction during vehicle operation.

- Supporting Renewable Energy: Electric vehicles with lightweight batteries can be charged using renewable energy sources such as solar or wind power, reducing the carbon footprint associated with the electricity used for charging.

Lightweight Car Booster Seat

Introducing the pinnacle of child safety and comfort on the road – the best Lightweight Car Booster Seat. Engineered with precision and designed with your child’s well-being in mind, this booster seat sets new standards for travel safety. Crafted from advanced lightweight materials without compromising durability. It offers effortless portability and easy installation, making it a versatile companion for all your journeys.CTEK – 40-206 MXS 5.0 Fully Automatic 4.3 amp Battery Charger

CTECK Fully enclosed design guards against sparks and reverse polarity issues High-quality input and output cables designed with strong strain relief Optimal for start-stop mechanisms, compatible with 100-120VAC and frequencies of 50-60Hz Activation possible from 2.0V, Battery capacity accommodates a range of 1.2 to 160 Ah.

Overcoming Challenges

Addressing common misconceptions and concerns surrounding lightweight car batteries is crucial for fostering trust in their viability. Despite concerns about safety, modern lightweight batteries undergo rigorous testing to meet stringent safety standards, often incorporating features like thermal management systems to prevent overheating.

- Pros

- Lightweight Car Batteries, a trans-formative innovation poised to redefine your driving experience.

- Lightweight Car Batteries boast a remarkable combination of power and agility.

- By shedding excess pounds, your car gains improved acceleration, enhanced handling, and increased fuel efficiency, contributing to a greener planet and saving you money at the pump.

- Cons

- Lightweight batteries often have lower reserve capacities, potentially leading to shorter run times if the vehicle’s alternator fails.

- Cold Weather Performance: In colder climates, lightweight batteries might struggle to provide sufficient power during startup due to lower cold cranking amps.

- Limited Heavy-Duty Use: For vehicles with high power demands, such as trucks or cars with extensive electronics, lightweight batteries might not offer adequate power supply.

Conclusion

Car batteries require more frequent maintenance and have a limited number of charge-discharge cycles, which can impact their overall lifespan. On the other hand, lightweight alternatives often exhibit better durability, longer lifespans, and the potential for faster charging, making them more convenient for consumers.

FAQ

What is the lightest type of battery?

The lightest type of battery is lithium-ion batteries.

Are lightweight batteries possible?

Imagine you have a remote-control car. Right now, the batteries it uses are heavy, which makes the vehicle feel rich, too. But if we could make those batteries lighter while still keeping them powerful, the car would be lighter and easier to move around. This means the vehicle could go farther on the same amount of energy. So, by using lighter batteries that are still strong, we can make a car go longer distances without needing to charge up as often.

What are the components of an electric car battery by weight?

Imagine an electric car as a big toy car that needs special batteries. These batteries are made using some materials like lithium, cobalt and manganese. Usually, the batteries in a regular electric vehicle weigh about eight bags of sugar (that’s the lithium part), 14 bags of sugar (that’s the cobalt part), and 20 bags of sugar (that’s the manganese part). But sometimes, if the battery needs to be really big, like in a Tesla Model S car, it could be as heavy as 62 bags of sugar, just from the lithium part! These materials help the car store electricity so it can drive without using gasoline.